|

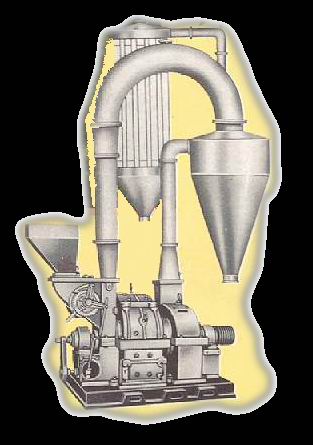

PULVERIZER

POWDERING

MACHINE FOR TEA

Aarkay's

'PULVERIZER' is a cold non-friction grinding machine with

combined grinding, classifying and conveying facilities in one

simple unit of robust construction made from graded cast iron

and alloy steel. This is designed to run continuously to grind

almost anything grindable like Tea, Drugs, Pharmaceutical

products, Chemicals, Pigments, Dyes, Tobacco, Spices, Food

Stuff, Coconut shell , Minerals etc., to the desired degree of

fineness. The machine is provided with fine system of

adjustment for fineness of finished products passable through

60 mesh to 300 mesh depending on the materials being handled.

The

main body is a compact unit consisting of feed hopper,

Automatic Rotary Feeder, Crushing chamber lined with breaker

plate, Balanced Forged alloy steel hammers, Mild Steel Wizzer

Classifier with adjuster for degree of fineness, Centrifugal

Blower. They all rotate on a single shaft driven by 10 H.P./

15 H.P. Motor, Interconnecting fabricated mild steel pipings ,

Cyclone for discharging the output and dust collector with

cotton anti-air-pollution dust bags are provided.

The

material to be pulverized is fed to the feed hopper which is

pushed by the automatic Rotary Feeder to the crushing chamber.

The high speed hammers inside the chamber with the finer plate

creates impact on the material in the rnid-air and breaks it

to finer grains. The ground material is carried to the Wizzer-classifier

which separates the coarser grade and passes the desired

grades. The coarse grades are returned to the crusher for

re-grinding. The desired grades are conveyed to the cyclone

for discharging to the bin. The cloth bagging dust-collector

is provided in the system for collecting the finer dust. This

ensures a dust free working atmosphere and rninimizes loss of

dust grade material by collecting them in the bags.

|

|

-

Capable

of pulverizing a wide variety of feed material including

Tea, Dry Ginger , Pepper / Burnt-Bones , Turmeric /

Shikakal , De-Oiled Cake / Urad Dhal , Charcoal , Starch

, Crude Drugs, Tamarind Seeds, Tobacco , Saw Dust /

Agarbatti , Raw materials , Coconut Shells, etc.

-

Output

capacity ranges from 15 kgs. (in case of Tobacco)

to 150 kgs. (in case of tea) per hour depending upon

type of feed material.

-

Low

Power consumption: Only one 15 H.P., 1400 RPM, 44OV, 3

Phase motor is required.

-

Compact

robust design. Space required is only 96" x

84" x 140" .

-

Automatic

rotary feeding.

-

Anti

- air pollution dust - free operation.

-

Non-friction

cold grinding process retains original quality.

-

3

in 1 operation - Grinding, Classifying and

Conveying.

|